Protection for the Machines We Rely On

Pro Industrial Coatings for Heavy Machinery, Agriculture, Construction Equipment, and More

CALL US (435) 383-8663 EXT. 3

Enhance Equipment Longevity with Industrial Coatings

In industries where machinery faces harsh environments, heavy usage, and constant exposure to corrosive elements, maintaining the longevity of equipment is absolutely crucial. TekShine’s high-performance industrial coatings are designed to provide robust surface protection for a wide range of machinery, from Ready Mix trucks to agricultural equipment, cranes, and more. These coatings are a durable shield holding up against wear, surface corrosion, and environmental degradation you cannot simply avoid. This helps our customers extend the service life of your assets and minimize costly repairs or replacements.

CALL US (435) 383-8663 EXT. 3

Versatile Applications for Varied Needs

Our industrial coatings are formulated to meet the demands of diverse sectors. We largely focus on agriculture applications, construction, marine equipment, and heavy machinery on various job sites. Whether you need protection from saltwater corrosion in marine environments or durability to withstand rugged agricultural conditions and contaminants, our industrial coatings deliver unparalleled performance. With tailored solutions for each industry, we ensure that your equipment remains in top condition, even under the most demanding circumstances.

We Are Your Trusted Partner for Equipment Protection

At TekShine, we take pride in offering reliable, high-quality industrial coatings that empower business owners to focus on productivity without worrying about equipment degradation. These coatings also give you the chance to preserve your equipment as assets to your business. Our commitment to innovation, product excellence, and high-quality application services ensures that every coating is applied with precision and care. Protect your investment today with TekShine’s industrial coating solutions! Call us at (435) 383-8663 or click below for a free price estimate. Learn more and schedule a consultation with us today.

CALL US (435) 383-8663 EXT. 3

Industrial Coatings Provide Protection in These Industries

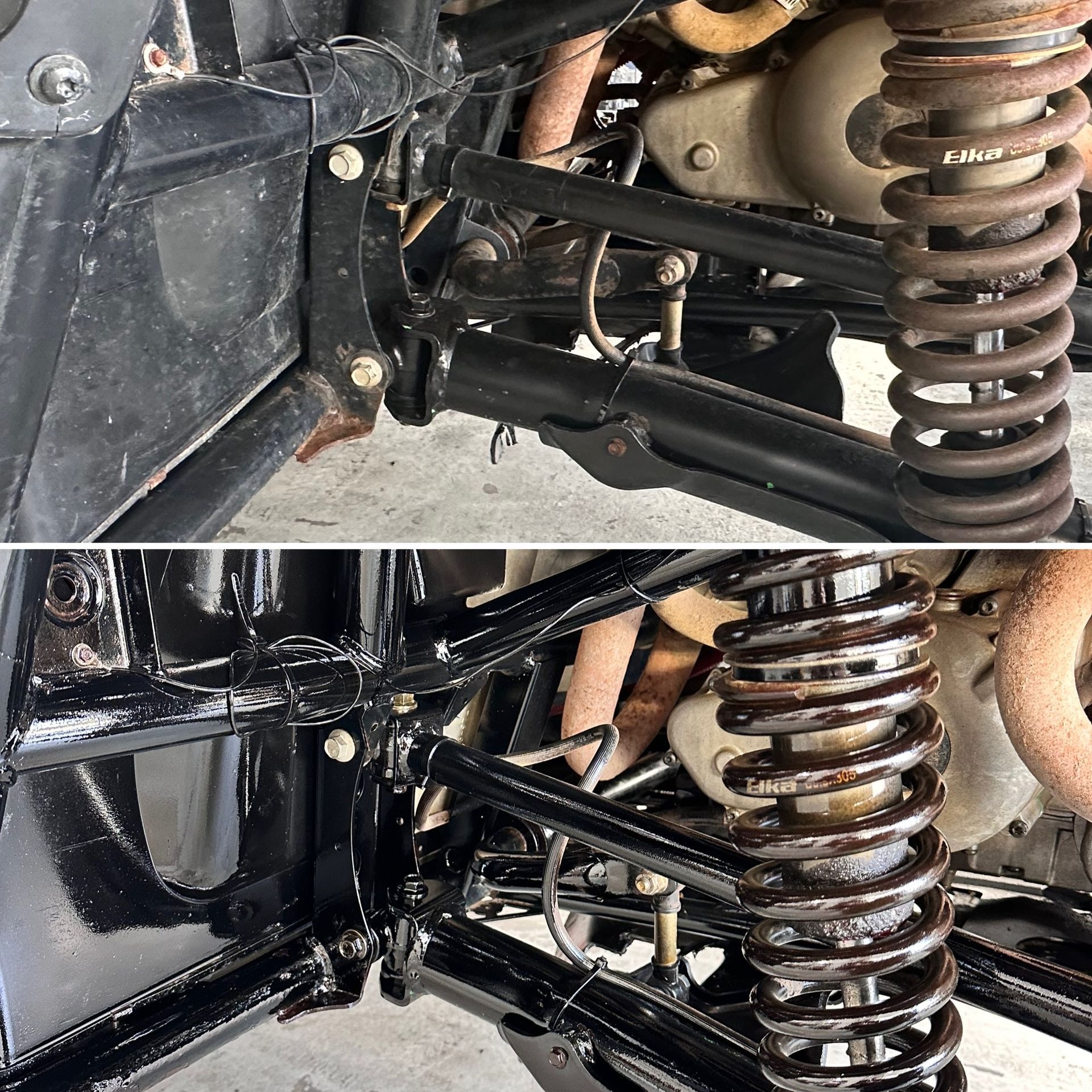

Automotive Industry

The automotive industry relies on our industrial coatings to protect the underbodies and road-exposed panels of vehicles. These coatings prevent rust and corrosion caused by road debris, moisture, and salt exposure, especially in Utah where winters are harsh. By safeguarding critical components, our industrial coatings improve the durability and safety of vehicles, ensuring they maintain their performance over time.

Aerospace Industry

In the aerospace industry, precision and protection are paramount. TekShine’s industrial coatings provide superior corrosion resistance and thermal protection for aircraft parts, ensuring they perform reliably at high altitudes and in extreme temperatures. Our industrial coatings help reduce maintenance requirements, enhance efficiency, and prolong the operational lifespan of aerospace components.

Marine Industry

Marine environments are notoriously corrosive. With saltwater and humidity causing significant wear on metal surfaces, TekShine’s industrial coatings are specifically designed to combat these challenges. In turn, we protect ships, boats, and marine equipment from rust and general degradation. Help maintain the integrity and functionality of your marine vehicles!

Construction Industry

Construction equipment, bridges, and buildings endure constant exposure to the elements. TekShine’s industrial coatings are essential for increasing durability and extending the lifespan of these structures. By applying our advanced coatings, construction companies can reduce maintenance costs and enhance the resilience of their projects, ensuring they stand the test of time.

Oil and Gas Industry

Pipelines, tanks, and other equipment in the oil and gas sector face extreme temperatures and corrosive chemicals daily as well. Provide a robust layer of surface protection with our industrial coatings and prevent those surfaces from experiencing a compromise in their integrity. With our solutions, oil and gas companies can operate more efficiently and safely, minimizing the risk of costly downtime.

Manufacturing Industry

Manufacturing machinery and equipment are exposed to heavy wear, tear, and chemical exposure that cannot be avoided. TekShine’s industrial coatings are designed to protect these assets, ensuring consistent performance and longevity. By reducing the effects of friction, corrosion, and chemical degradation, our coatings help manufacturers maintain productivity and avoid frequent equipment replacements.

COMMON QUESTIONS ON TEKSHINE INDUSTRIAL COATING PRODUCTS

Product Functionality and Benefits

Application Process

Durability and Maintenance

Cost and ROI

Compatibility and Safety

Performance in Construction-Specific Scenarios

Customization and Support

Smooth. Shiny. Smart.

TekShine Industrial Coatings provides cutting-edge surface protection solutions designed to outlast and outperform the competition. Our product lineup—Purge, Titan, and Titan Max Release—offers superior durability, corrosion resistance, and hydrophobic properties, keeping equipment clean, dry, and in peak condition. Unlike traditional coatings and cleaners, TekShine Industrial products are VOC-compliant ensuring safety for both users and the environment. From mining to marine and aerospace, TekShine delivers industrial-grade strength and fast application, minimizing downtime and maximizing efficiency. Proudly made in the USA, TekShine Industrial is your partner for lasting performance in the toughest environments.

Quick Links

Our Location

1220 Sage Dr, Cedar City, UT, 84720, United States

Contact Us

Phone: (435) 383-8663 ext. 3

Email: office.bc@tekshine.com

Hours of Operations

Monday-Friday: 8:00 AM - 5:00 PM, By Appointment Only

Saturday-Sunday: Closed

Additional Service Areas

Social Media

This website was designed by the team at Detailers Roadmap, a platform developed for detailing operators across the globe.